Obsah

Active Softstart for Welders

This covers softstart circuit designed especially for upgrade of cheap MIG/MAG transformer welder.

Problem

- Welder triggers the 16A/B circuit breaker during switch-on phase (when the torch trigger is pressed)

- This is caused by inrush current spike before transformer core get magnetized

- MIG/MAG welder usage means frequent switching of primary and has to respond immediately

- Can't use NTC termistor because it works only when it has enough time to cool down before repeated power on.

- Can't use delayed switching relay circuit for premagnetization circuit because it would not switch fast enough for short welds.

- Can use peak-switching SSR (solid state relay) with proper rating. These are designed to fit this use, but they are rather expensive and hard to find. This makes them impractical for using with cheap hobby-grade or old welders (which are probably only ones that need this as inverter based welders do not need softstart)

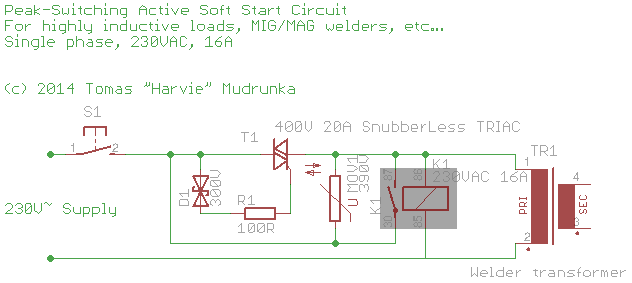

Schematic

Working principle

It exploits the fact that current in transformer is 90° out of phase of the voltage, which leads to conclusion that best time to switch on the transformer is in voltage peak of mains power line (which was quite counter-intuitive for me at the first time). This circuit detects the peak using 300V bi-directional transil (TVS diode) which is then used to trigger snubberless TRIAC which switches on the power transformer of welder. Once this happens, there is normally open relay with AC coil connected in parallel to transformer which shorts out whole active circuit and therefore prevents any excesive heating caused by high currents through semiconductor components (= No heatsinking needed!). To make circuit more robust and endurable there are two more components to prevent possible damage to semiconductor elements. In series with TVS there is resistor to limit current through TVS and to TRIAC's gate. Also there is 390V varistor across the whole switching circuit which prevents voltage spikes from transformer to kill the TRIAC and partially helps to supress arcing in relay contacts.

Notes

- You can probably try it without varistor (however blown varistor is cheaper to replace than blown triac)

- You can probably try it without current limiting resistor (haven't tried this, resistors are cheap, but let me know…)

- You should use snubberless triac, i haven't tried, but it may work with regular triac (in worst case you'll need to add "snubber" RC circuit across the triac to filter the spikes)

- You can experiment with transil values from 280V to 315V

- higher value = more precise peak detection, but don't overdo it. otherwise line will not have sufficient peak voltage to trigger the switch.

- 230VAC line has peaks of approx. 320V but there can be some fluctuation, brown outs and actual voltage of transils can be slightly different from nominal (see datasheets for info on precision/tolerance)

- I did not managed to get 300V bi-transil (TVS), so i've used two 150V ones in series.

- It's designed for 230V~ grid, if you live in 120V~ country then you should make these (obvious) changes:

- use relay/contactor with 120V~ coil

- use 150-160V bi-transil to trigger the triac instead of 300-310V (otherwise the transformer will not start)

- use 190V varistor instead of 390V (used for 230V~). This is not needed, however it should make circuit more endurable

- maximal voltage of triac doesn't matter, the higher the better. i use 400V at 230V~ line (which is good as my varistor should keep the spikes below 390V = use triac with higher voltage than your varistor)

- Circuit will probably need complex review before using with 3-phase appliances/welders.

Testing

As i currently lack proper testing equipment i can't give you precise numbers. I've measured maximum current in primary winding of welder transformer (without load) using "HIOKI 3291 clamp on HiTESTER", which has "MAX" function, however i think it's too slow to properly capture initial inrush current peak. Without softstart maximum read 15.09A and with softstart it read 3.43A. But these numbers are NOT real current peak as 13A could not trip 16A circuit breaker. But you can at least see some proportional improvement between those two values…

Photos

Passive version

However the active version using TRIAC is superior, there is also other possibility which doesn't perform so well, however is little bit easier to build.

http://www.svarbazar.cz/phprs/view.php?cisloclanku=2007080801

Problem is that it relies on mechanical delay of relay contacts. I've tried with small 230VAC relay and it did not prevented circuit breakers from being triggered by welder completely. (probably you should use big contactor for better performance).